Being able to hold something in my hands that I made in Mudbox is pretty cool. Kinda like ‘TEA / EARL GREY / HOT’ but much slower and entirely plastic.

My 3D printing process

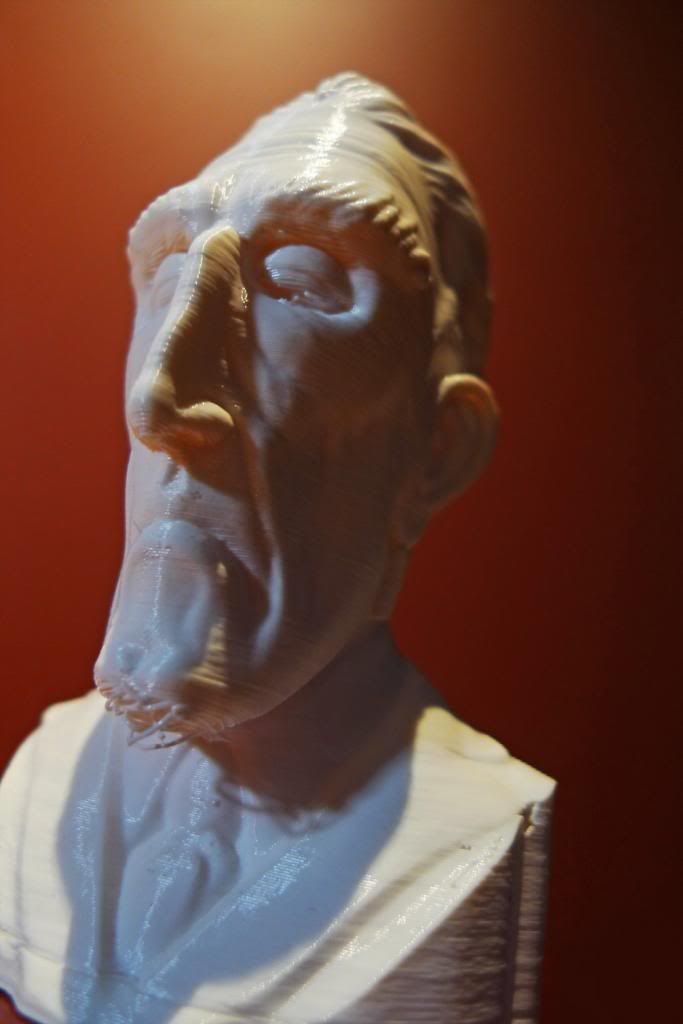

I printed the butler! Here’s the vid of his creation in Mudbox.

After he finished, I exported the high-res mesh to Maya. He wasn’t too many polygons, so Maya handled it ok. Once there, I extruded his bottom verts straight down to create a flat base to stand up on.

The hard part is to start thinking in the real-world after years of using 3D software, all of which ignore the rules of reality!

Next was hollowing him out, both to save material and also so it wouldn’t take like a week to print.

To hollow him out, I duplicated the mesh, then ran a Mesh > Reduce on the whole thing. I used Edit Mesh > Transform Component to basically shrink him inwards.

I combined the original high poly with the new, shrunken, reduced mesh. I simply bridged the verts at the base of the mesh to seal it up and make it water tight.

As you can see the process was far from perfect, that’s why his chin exploded and it looks like he is wearing weird earrings.

The chin was a common problem – an undercut that was too steep. I built a support but it broke off before the print head got to the chin!

The ‘earrings’ are the same kind of supports, created in Mesh Mixer; they just wouldn’t break off easily.

I printed him on MakerBot’s Replicator 2, using ReplicatorG software instead of the default MakerWare. I used True White PLA Filament.

There was definitely a lot of trial and error, here are some of the unfinished prints:

In every case, the unfinished prints were due to nozzle jams, largely because the platform wasn’t well calibrated.

Backlighting here shows the huge gaps between layers on the bad prints.

What do you need to know to start 3d printing?

The biggest challenge for me, and for any 3D artist, is to start thinking in reality when printing. This is easier than it sounds, considering how often we ignore reality when modeling and sculpting!

Ok, that, and making the printer work. It wasn’t easy, it is definitely not a consumer-friendly product! Be ready to do your research and tinker a lot. Reddit’s 3D printing subreddit was a lot of help here!

How long do you think until the res in the 3d prints can be as detailed as a sculpt in mudbox or maya?

The super-expensive professional grade prototyping machines can probably already do that. For the desktop/hobbyist printers, I’d guess 2 or 3 years at least.